RAD PAD

As a pipemaker, I don’t succumb to PAD (Pipe Acquisition Disorder) too often. If I see a pipe I just have to have, I typically try to make it myself. However, there comes a time when even a pipemaker needs to buy a pipe.

I think that one of the best ways you an show an artist respect and appreciation for their work, is to buy something from them, directly, and at full price. Hence, the need for my Rad PAD.

Rad Davis is a well known wonderful pipe maker. He’s been in the business for the last 10 years, and just happens to live only 25 minutes away from me! When I moved out here to Alabama, I wasn’t really making pipes yet. I had only fiddled around with one or two. When I found out there was a master pipemaker in the “neighborhood” I knew I simply had to see if he’d let me come visit his shop.

After getting completely settled in my new house I connected with Rad and asked if I could come see his shop. I figured that if anything, I might pick up a little on how pipes were made, and what tools I should. Rad very generously suggested that if I came over early, I could see him make a pipe from start to scratch. I was floored and ablaze with excitement to say the least. Here I had the rare opportunity to watch a master craftsman make an entire pipe.

Long story short, after about 5 hours of watching Rad perform what seemed like magical acts of pipe carving, I came out enlightened, and a bit dizzy trying to make sense of all the information I had just gathered. It was that day that I decided to sell my favorite BMW 740i and buy the same tools he had so that I could make pipes as he does.

After about a year of making pipes and several trips to Rad’s house it became time to show my appreciation for his help, kindness and friendship. I needed to buy one of his pipes. Not only did he make me exactly the pipe I wanted, I got to watch him make it from start to finish, just like my very first experience with him. It was a very special time for me indeed.

So, without further ado, here is my RAD PAD:

How would a Growley pipe hold up if a “Hun” were smoking it?

How would a Growley pipe hold up if a “Hun” were smoking it? Well, we will just have to wait and see.

Several weeks ago I was contacted by Darryl Quon. He wanted to know if I’d make a Devil’s Anse pipe for him. Seeing that I love to make that particular pipe, I gladly accepted.

As with with most of my customers, Darrel and I have exchanged several friendly email messages. He mentioned that he had been busy “On Set” all day and apologized for a late response to one of my messages. Not being able to restrain my curiosity, I asked him what he does on set.

It turns out that while Darrel is an extremely nice and pleasant person to talk to, he’s also a killer, kick butt, no nonsense, run around on fire and punch people in the throat stuntman and actor. He’s been in a variety of wonderful movies including one of my (and my kid’s) favorites, The Night At The Museum”, in which he was one of the fantastic Huns who was ready to tear Ben Stiller into pieces.

The Devil’s Anse pipe made it to Canada where his wonderful new owner will put it through it’s paces. If Darryl treats his pipes like he does his coworkers, then I probably should have ruggedized it…

CONTEST WINNER ANNOUNCED!!!

First of all, I’d like to thank all of you who have entered my pipe give away by signing up for my Inform Letter. From here on out, you’ll be the first to know when a new Growley pipe becomes available.

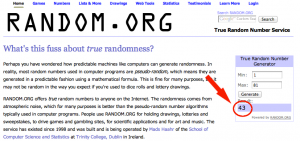

There were 81 total entries. Each entry was assigned a number according to when they were received (from 1 to 81). To randomly pick the winner, I used www.Random.org which uses the randomness of atmospheric noise to truly pick randomly.

The WINNER, as chosen by Random.org, is #43.

The number 43 belongs to gXXXXXXy@gmail.com (the X’s have been used to protect the winner’s identity)

Congratulations gXXXXXXy@gmail.com! I will be contacting you for your shipping information.

Thanks again to all of you for your participation!

I’m sure this won’t be my last give away…

Brian.

GrowleyPipes.com Kick-Off Contest!

Hey all. This is your chance to own a Growley pipe for free. As a “Thank You” for taking an interest in my pipes, I’d like to give you a chance to WIN this pipe. All you have to do is sign up for the “Email Newsletter” which is less of a newsletter and more of an “inform letter” to let you know when a new Growley pipe that is available for purchase.

How to enter:

Just enter your Email address in the “Email Newsletter” box and hit submit. Your email address will coincide with a number on a simple Excel spreadsheet. Those numbers will be entered into a randomizer which will pick 1 number, the winner! The winner will be drawn on Friday, the 3rd of August.

Thanks again for your interest, and good luck!

Below is the prize pipe, a bent Brandy

The dimensions are as follows:

Length – 5.25″

Chamber Depth: 1.45″

Chamber Bore: .75″

A Ramses Commission: The Journey

A fun and tense part of my work is commission work. Recently I took on a Ramses commission for a customer. The Ramses design was originally designed by the great Bo Nordh. Bo was the original creator of the Ramses shape. This shape is very difficult for many reasons. Probably the most difficult for me is the drilling. The drilling angles are so steep that it’s very easy to drill wrong and either have the draught hole enter the chamber way too high, or have it end up being oblong making it too big.

Here’s a picture of the block drawn up and ready for drilling:

Once the appropriate angles have been determined the drilling begins…

I can easily spend an hour at this stage, fidgeting with angles, widths, measurements and so on just to make sure it’s perfect. As my grandfather always said, “Measure twice, cut once”. I think I measured this a dozen times, just to be sure. But in the end, it’s worth it. The drilling happened as planned, a nice size draught hole at the bottom center of the chamber. Here’s a pic of it drilled.

Now that it’s drilled it’s time to fit the stem. All of my stems are hand cut. This one will be a saddle stem created from ebonite. Shaping without a stem attached for this kind of pipe is typically counterproductive.

Ok, I have a snug fitting stem cut so it’s on to the part I love the most, the shaping! This is the second most difficult part of this particular pipe. All of it has to be done by hand and a Ramses has a number of curves, lines and facets, all of which have to pace nicely together.

The back side of this Ramses is curved almost like a surf board, while the bowl has a similar shape to a jet engine on a 747. The two have to come together as one piece. If placed right in the block, the grain will start from the back (surfboard) leaving a wonderful birds eye across the entire plain, and stretch all around the sides of the bowl (jet engine) finishing in a birds eye across the belly of the front. With the right block of wood, this can have a wonderful effect.

Before doing too much more work on the stummel, it’s time to get to work on that stem. Saddle stems finish this shape off nicely, but take a bit more work to open them up properly so that they smoke open and free of resistance. This is a process that can easily take me an hour to complete.

Rough cut of the stem…

After about an hour of sanding, staining and polishing, here’s the final product…